Reproducibility of Test Results

2022-10-13 14:13

Many customers are asking us: Why the same product has the same test requirements, but the test results are not exactly the same? Where is the problem?

In addition to the repeatability of instruments and tooling, this also involves some external factors.

According to the ideal gas law equation pV = nRT, (P: test pressure, V: test volume, n: amount of gas substance, T: gas temperature; R: constant), we can see the main factors that affect the repeatability of test results There are the following aspects:

1. Change in temperature

(1) The process of pressurizing the gas in the test workpiece must be accompanied by the process of doing work. Because the space for the movement of molecules in the gas is small, the movement is relatively violent, so that the temperature of the internal gas changes, and then the temperature is slowly affected by heat transfer. consistent with the outside world.

Recommendation: Increase the stabilization time.

(2) The temperature of the test workpiece is inconsistent with the surrounding air temperature. For example, the test workpiece has been processed by high temperature cleaning, drying, heating furnace, refrigerator, welding, compressor, etc.

Suggestion: Blow air to cool or wait until it is consistent with the normal temperature. The same test workpiece cannot be tested immediately after the test is completed. It needs to be placed at normal temperature before testing again.

(3) Affected by external heat, such as: standard products (especially products that are sensitive to temperature transfer), piping, tooling, etc., heat will be transferred to the inside of the test workpiece, resulting in temperature changes and test errors.

Suggestion: Prevent the interference of external wind caused by air-conditioning wind, fan, machine air outlet, and door switch. Do not touch the test tube with your hands during the testing phase. When conditions permit, you can add a thermal insulation sleeve to the test tube.

(4) Test the humidity of workpiece and fixture

Recommendation: Dry or wait until dry before testing.

(5) The switching valve in the middle of the test tube is heated

Recommendation: Use a non-heating valve body, such as an air-operated valve.

(6) How much influence does temperature have on air tightness detection? We can calculate it according to the following formula (derived from the ideal gas equation):

Δt: Temperature change [°C]

∆Pt : Pressure change [Pa]

P: Test pressure [kPa]

t: Test temperature 20℃

2. Change in Volume

(1) Deformation of the test workpiece: The test workpiece is slightly deformed

during the detection stage, and the deformation coefficient is not exactly the same each time.

Recommendation: Increase the stabilization time.

(2) Creep of the sealing material

Suggestion: replace the sealing material, use a precision pressure regulating valve to control the air source pressure of the cylinder, the regulation pressure must be lower than the factory minimum air source pressure, and increase the physical limit to reduce the impact.

(3) Deformation of the test tube: The test tube is soft and expands under pressure, and the deformation coefficient is not exactly the same each time.

Recommendation: Both the test end and the standard end are connected by hard pipes.

(4) The pressure source is unstable: for example, the cylinder pressure increases or decreases, the volume of the sealed workpiece end changes, and the sealing sealant creeps.

Suggestion: Use a precision pressure regulating valve to control the intake source pressure of the cylinder, and the regulating pressure must be lower than the factory minimum air source pressure

3. Other factors

(1) The sealing ring is damaged or dirty

Suggestion: replace the sealing ring

(2) Scratches or dirt on the sealing end face of the workpiece

Suggestion: wipe the sealing face of the workpiece or replace the test workpiece

(3) External factors: such as personnel walking, ground vibration, and obvious changes in the temperature of the working environment.

Recommendation: People around the test bench should not move around, no heavy objects are moved, and the temperature and humidity are constant.

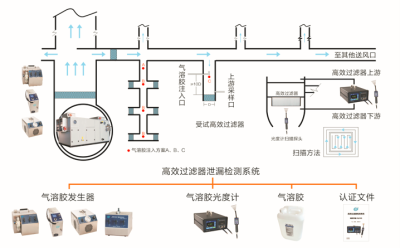

Shenyang Golden Tech Precision Instrument & Equipment Co., Ltd. is a professional manufacturer of air leak testers and flowmeters. We not only have cooperated with thousands of enterprises for more than 30 years, but has good brand influence and professional service capabilities.

We are excellent and trusted partner in your success!

Get the latest price? We'll respond as soon as possible(within 12 hours)